Mill Roll NCCM® N-Series – N2 | NS | NT

Mill Roll NCCM® N2 is a high-performance N-series product for a variety of neutral solution applications. With a much longer service life than rubber or polyurethane rolls and an excellent cost-benefit ratio compared to other nonwoven coverings.

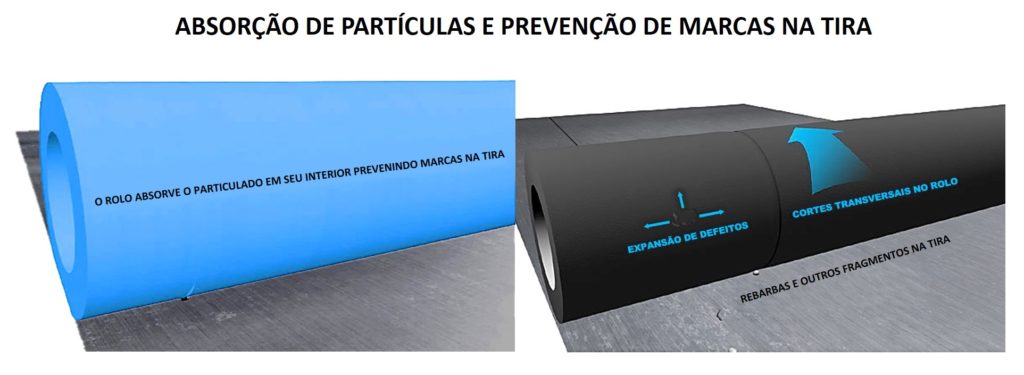

Mill Roll NCCM® NS uses Soft Touch technology and is indicated for applications on surfaces that require better surface quality, operating at lower pressures and without causing marks and scratches. This cover shows excellent results on wringer rolls applied in reversible rolling mills of stainless steel and other non-ferrous materials.

Mill Roll NCCM® NT is a competitively priced nonwoven roll intended for pinch/feeder roll applications, squeezers and as transport rolls, as long as they operate at lower clamping pressures. Due to its low compactness and high porosity, this cover is commonly applied in vacuum wringer rolls, with a high fluid absorption and excellent drying.

Main Advantages of the N-Series Line:

- Excellent cost x performance ratio;

- Moderate to long life;

- Cut resistance;

- Superior fluid control.

- High coefficient of friction;

- Self-healing;

- Custom engineering.

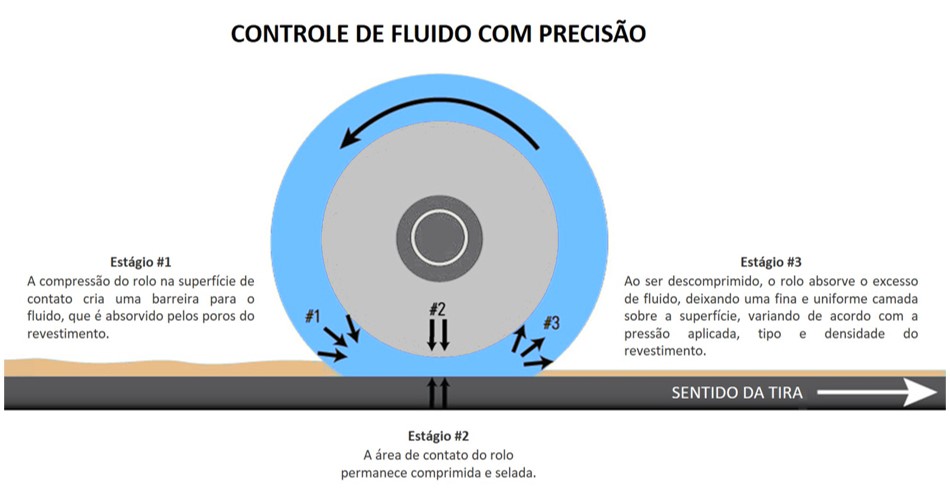

Fluid Control with Precision

The porosity and compressibility of Mill Rolls ensure consistent fluid control performance. The amount of residual fluid can be precisely adjusted for your application by proper liner specification and adjustments to process operating parameters.

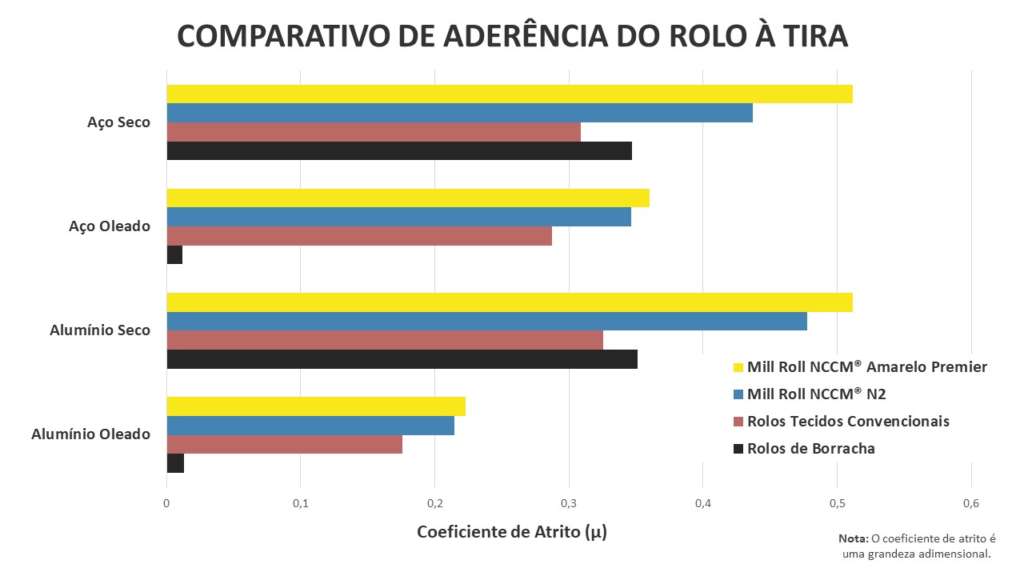

Coefficient of Friction

The high coefficient of friction of the Mill Roll NCCM®️ N-Series is a globally proven benchmark, specifically for oiled steel and aluminum surfaces. The usual problems generated by strip slippage can be eliminated by installing a Mill Roll on your line.