Mill Roll NCCM® CX-Series – Chemicals

Main advantages:

- Chemical resistance to most alkaline and acid chemistries;

- Resistance to cuts resulting from the strip width variation;

- Prevent fluids cross contamination between tanks;

- Lower energy costs;

- Reduced maintenance costs;

- Improved process control;

- Fewer defects on the strip surface;

- Reduced line downtime.

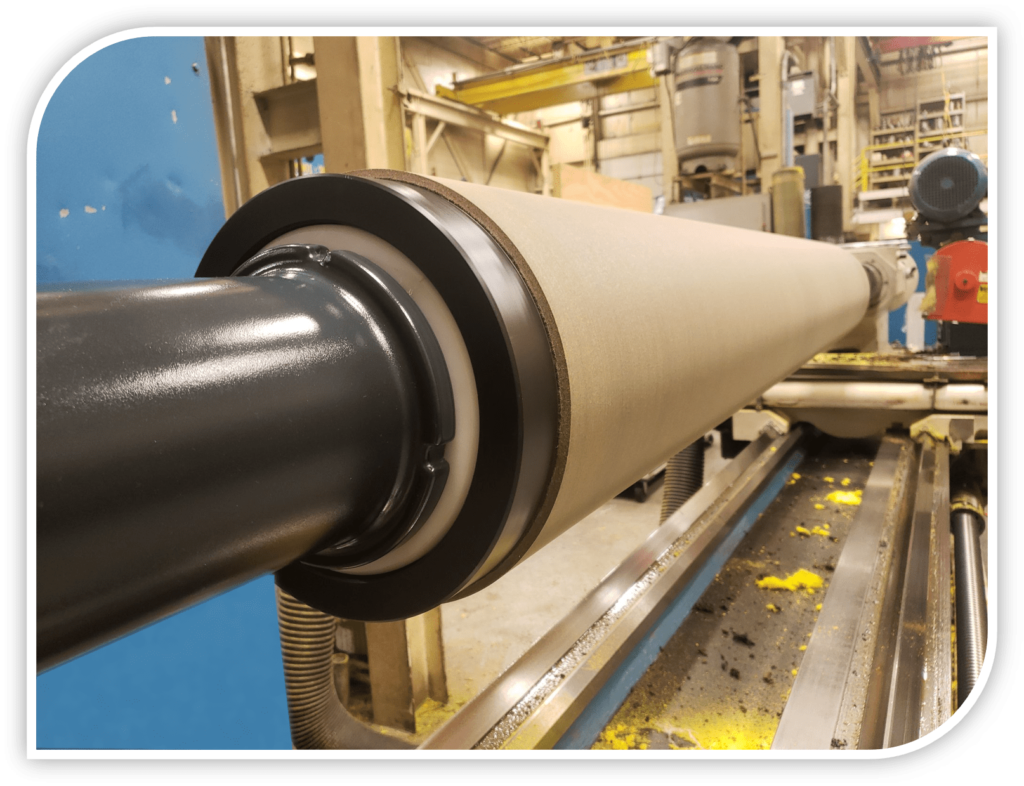

NCCM®️ CX and CX-Plus are specially designed to operate in aggressive chemical environments, such as electrolytic galvanizing and tin plating lines, pickling lines, painting lines, and at the exit of alkaline tanks in degreasing sections.

The uniform porosity of the nonwoven rolls and their ability to maintain continuous contact with the strip make these cover excellent applicators, ensuring even distribution and no wasted solution on the strip.

When applied as wringers, they demonstrate a significant reduction of carry over and cross-contamination of chemicals from one tank to another, contributing to the reduction of fluid and waste disposal costs.

Their high coefficient of friction reduces sliding and aquaplaning for better control of the processed material.

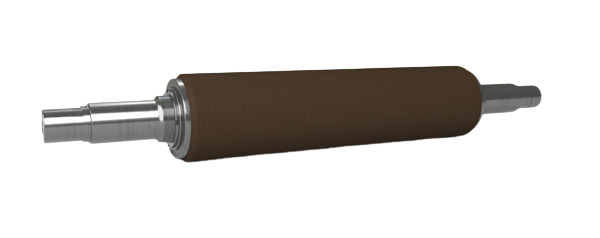

NCCM® CX

CX rolls have excellent lifetime and wringing capability in caustic and acidic environments. Their regeneration properties provide cut resistance against strip edge damage and wear resistance extends rolls’ lifetime far beyond traditional rubber coverings.

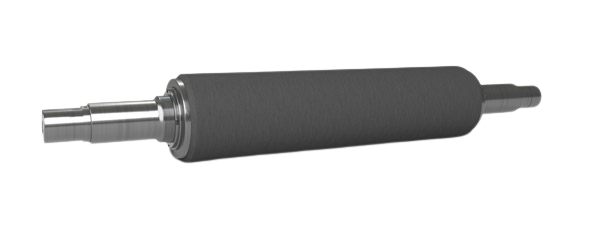

NCCM® CX-Plus

CX-Plus rolls excel in environments with higher temperature and pressure requirements than NCCM® CX rolls can meet. Long life and cut resistance separate CX-Plus nonwoven rolls from traditional materials that wear and break down quickly.