MILL ROLL NCCM® Premier Yellow

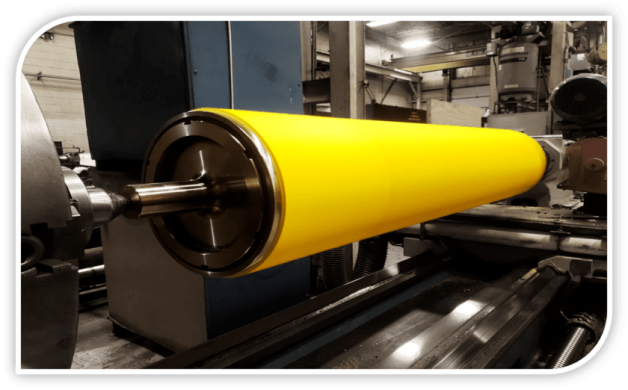

Mill Roll NCCM®️ Premier Yellow is manufactured from originally yellow nonwoven fibers produced exclusively by 3M Company.

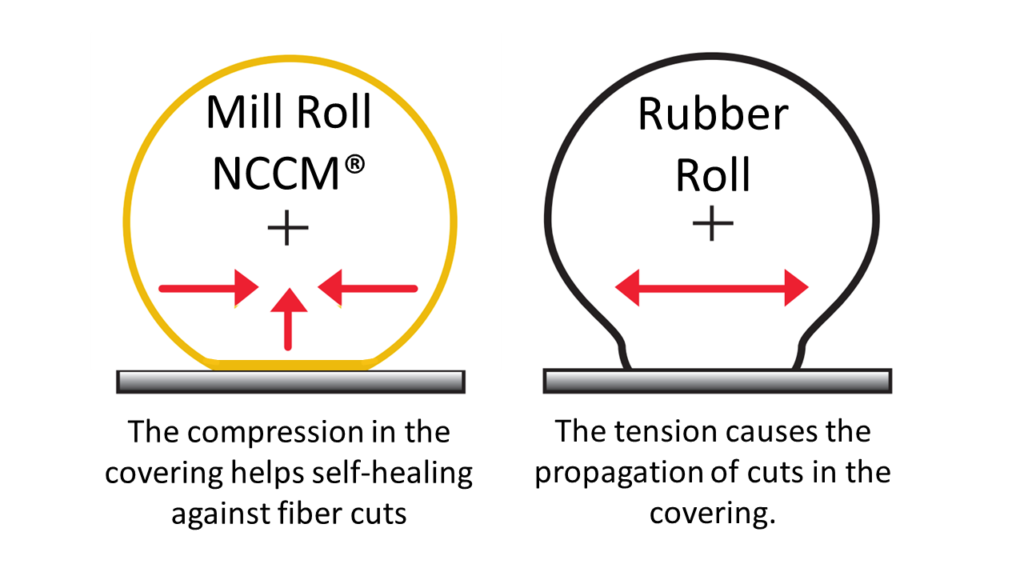

Constructed from individual discs of synthetic nonwoven fiber bonded with a strong and flexible adhesive for a unique combination of characteristics, including resilience, cut resistance and regeneration, porosity and absorption. NCCM®️ nonwoven rolls last longer and generate less maintenance downtime, which helps improve quality control and process consistency, ensuring significant contributions to increased productivity.

Application of NCCM® Mill Rolls in Primary Metal

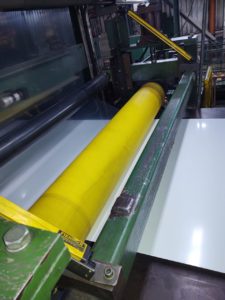

NCCM® Mill Roll Premier Yellow is the main cover applied in wringing, oiling and tensioning rolls for coil and sheet processing lines, with higher mechanical and thermal resistance, to work in neutral solutions (pH between 2 and 10), surpassing all other conventional rolls.

Main advantages of Mill Roll covers:

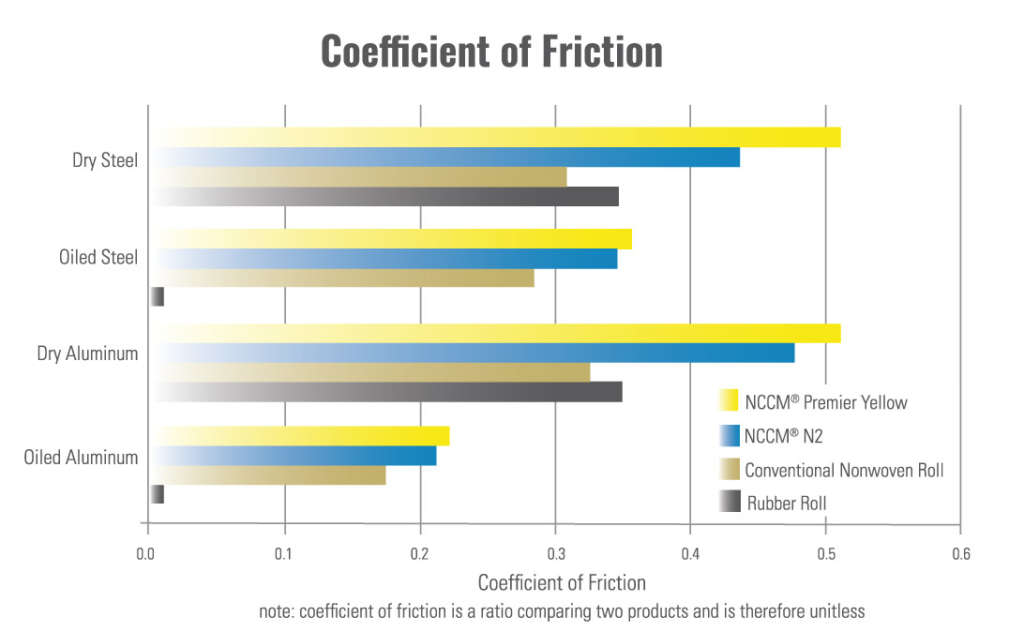

- High coefficient of friction (dry or oiled) reduces strip slippage and hydroplaning of the sheets;

- Longer service life with multiple operating campaigns;

- High coefficient of friction (dry or oiled) reduces belt slippage and hydroplaning of the plate;

- Greater resistance and regeneration to cuts, with the possibility of partial or total repair in case of damage;

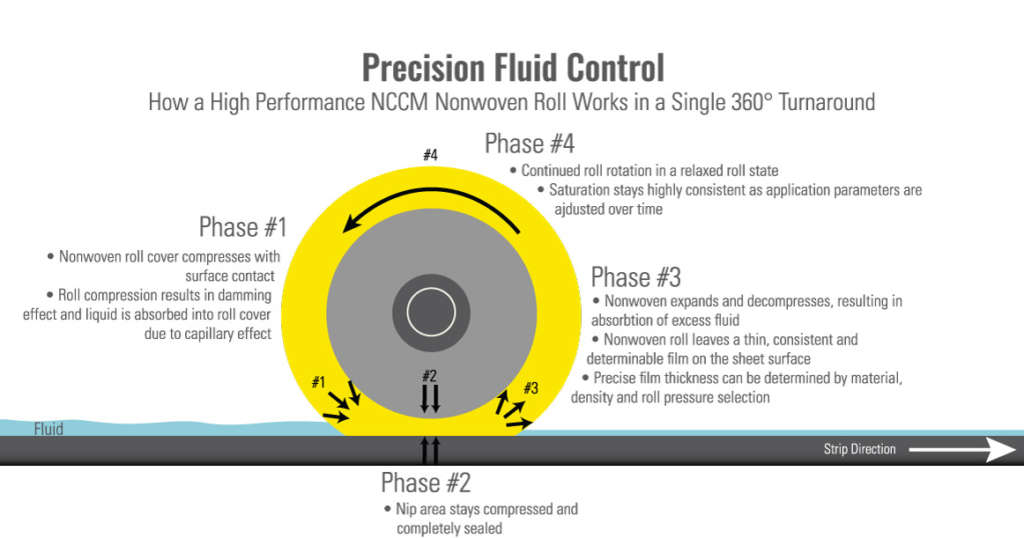

- • Greater precision in fluid control.

Most common application sites:

- Pickling Lines;

- Continuous Annealing Lines;

- Electrolytic Galvanizing Lines or Hot-Dip Galvanizing Lines;

- Electrolytic Tinning Lines;

- Electrolytic Cleaning Lines;

- Continuous Painting Lines;

- Cold Rolling Mills and Skin-pass Mills;

- Reinspection Lines;

- Slitters, cross-cutters and blanks washers.

Main applications of Mill Rolls:

- Wringer Rolls;

- Oiling / Applicator Rolls;

- Pinch / Transport Rolls;

- Deflector Rolls;

- Tension Rolls.

General benefits for the process:

- Increased line availability (+ productivity);

- Waste reduction and fluid cost savings.

- Reduction of defects on the surface of the sheets.

Comparative: Mill Roll compression vs. Rubber Roll tension

Application of Mill Rolls in the Automotive Industry

When applied to blank washers in the automotive stamping segment, Mill Roll NCCM® Premier Yellow is incomparably superior to any other non-woven covering, with a durability of 2 to 5 times longer, maintaining its initial characteristics – precise control and homogeneous distribution of the oil film – throughout its lifetime. Another unique feature of Mill Rolls is the possibility of partial repair of the roll face in case of accidents, caused by bending of the blanks inside the washer or by superficial cuts coming from the sharp edges of the blanks.

Precision Fluid Control

The porosity and compressibility of NCCM®️ Mill Rolls ensure consistent fluid control performance. The amount of residual fluid can be fine-tuned for your application by proper specification of the cover and adjustments to process operating parameters.

Friction Coefficient

The high coefficient of friction of the Mill Roll NCCM®️ Premier Yellow is a globally proven point of reference, specifically for oiled steel and aluminum surfaces. Common problems generated by strip slippage can be eliminated by installing a NCCM® Premier Yellow on your line.