EVALUATION AND REPAIR OF ROLLS

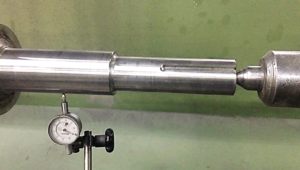

Rolls mechanical and dimensional evaluation service, including or not the execution of non-destructive tests (penetrating liquid, ultrasonic and magnetic particles), detecting defects and irregularities in the core shafts before they result in serious damage.

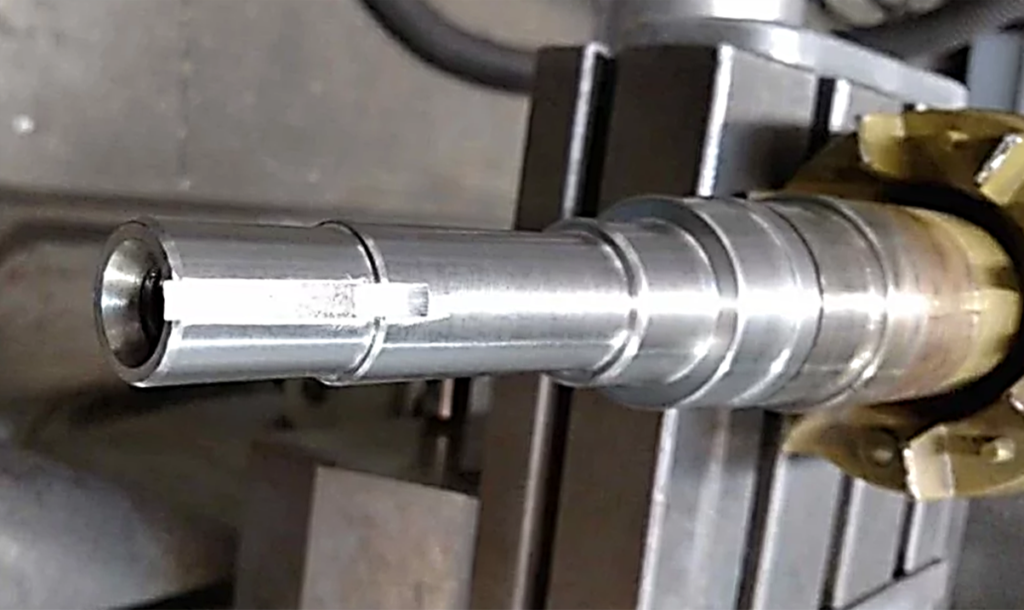

Repair of shaft bushings, bearing collars, threads, keys and lubrication channels, restoring the rolls to their original condition for the assembly of Brush Rolls or Mill Rolls.

Pre-assembly service for components on the rollers, such as: bearings, application of grease, retainers, couplings, drip collars and balancing flanges.

Dynamic balancing of shafts and assembled sets according to ISO 1940 Standard in Classes G 6.3 or 2.5.

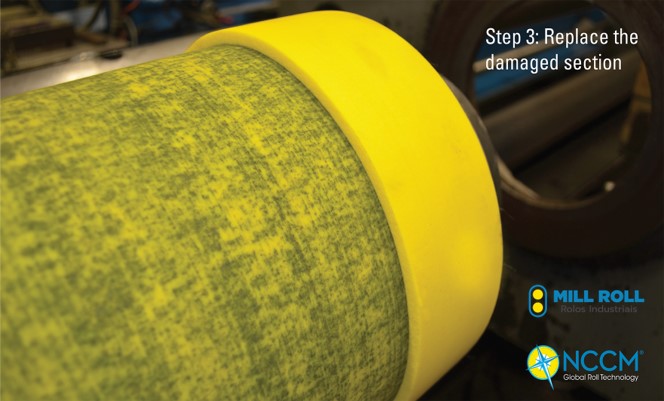

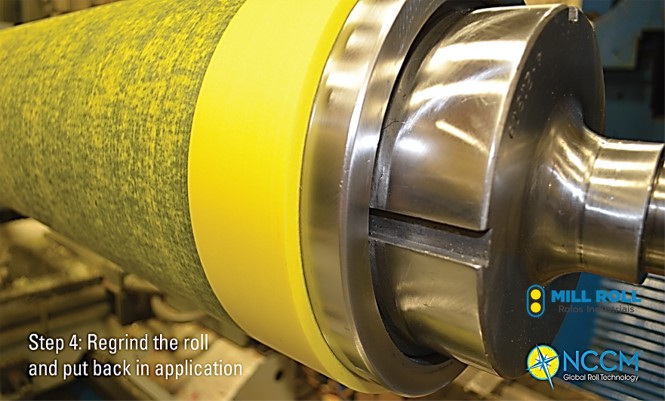

Partial Repair of an NCCM® Mill Roll Cover

Partial repair of Mill Rolls with the replacement of the damaged area of the cover and subsequent grinding of the roll face, flat or crowned. Surface thinning and complete grinding of the roller face to clean its pores and recover its properties, restoring the “sponge” effect.