OIL THICKNESS MEASUREMENT - PLATE OUT

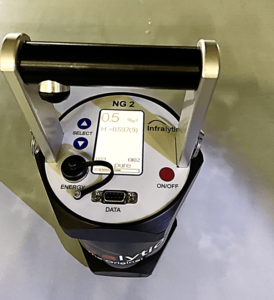

The oil film thickness measurement service is performed by Mill Roll with the use of a portable scanner, with high-precision infrared light technology. The measurement is performed in fractions of seconds and the results are presented in g/m² or mg/m².

The equipment has a graphic display for immediate reading, but the measured values are stored internally and can be downloaded as spreadsheets when necessary.

Its field of application ranges from post-rolling processes, where the initial oil is applied against corrosion, to service centers that need a suitable oil film for cutting and forming processes, or where the absence of oil is essential in the application of coating or paint on the metal surface.

When producing and processing steel and other metals, it is essential to take regular measurements of the oil film thickness. However, traditional methods are laborious, expensive and/or time-consuming. The more accurate the control of the applied oil film, the greater the opportunities for optimization of the rolling, degreasing, stamping and painting processes, among others.

Calibrations of materials available in the equipment:

- Cold-rolled strips;

- Galvanized sheets by hot-dip immersion, or electrolytically;

- Tin, nickel or phosphatized plated sheets;

- Galvanneal or galvalume plated sheets;

- Aluminium (lamination finish and EDT);

- Other calibration options on request.

Main advantages of the Measurement System:

- Accuracy of measurement;

- Immediate measurement result;

- Flexible use in various environments.