On-Line Surface Cleanliness Measurement

IMPORTANT INFORMATION

- The laser energy does not damage the strip surface.

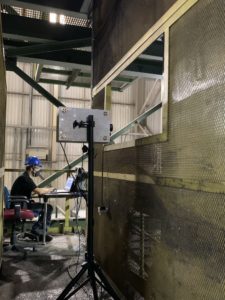

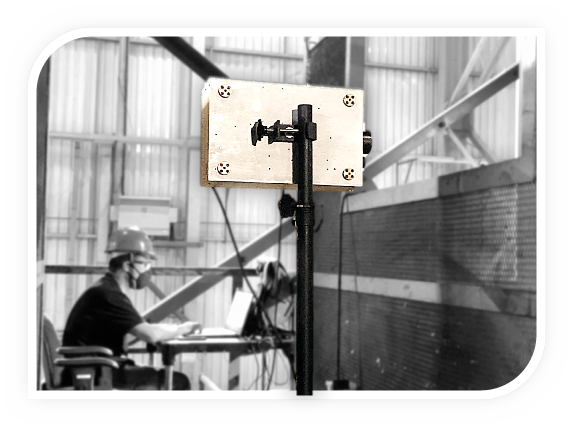

- The TST.one device is positioned in the center or on the edges of the strip according to the customer's interest;

- The surface contamination content is proportional to the intensity of the plasma generated by the laser blast;

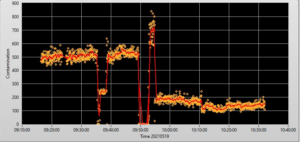

- The measured results are presented in graphs with a scale of dirtiness vs. time of reading, highlighting all the events that took place on the line during the measurement.

The measurement service quantifies the dirt on the strip surface in real time, directly on the production line, without contact or any risk of damage to the material surface. The measurement of dirt particles, including rolling mill oil and iron fines, is performed by emitting intermittent laser pulses on the strip to ablate contaminants into a plasma, and capturing the light intensity generated by this spark.

The measurement service with the laser – TST.one is usually performed by Mill Roll at the entrance of the line, and later at the exit of the cleaning section, in order to compare the efficiency of the process. It also allows us to compare the different impacts on the superficial cleanliness of the material by means of changes in the line’s operational parameters, such as: variations in speed, in the pressure of the brush rolls, inversion of polarity of the electrolytic cleaning section, among others.

Based on the results measured by the equipment, our technical team is able to present solutions to improve the performance of the cleaning section, through the use of different technologies in Brush Rolls and filaments, and the application of high-performance Mill Rolls as wringers, with a significant reduction of carry-over of solutions and cross-contamination between the tanks.