MILL ROLL INDUSTRIAL ROLLS

The company Mill Roll Rolos Industriais Ltda came from the entrepreneurial initiative of a team of professionals with extensive technical knowledge in the steel and automotive markets, with the objective of offering locally the most modern technologies used worldwide in cleaning systems and fluid control in metal processing lines.

OUR PRODUCTS AND SERVICES

NCCM products combine the best materials with high-production technology and custom engineering to create product lines designed for high performance.

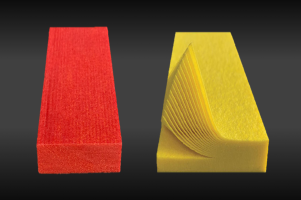

Nonwoven rolls can last up to 100 times longer than other rolls and provide several other benefits.

The bars are made of compressed non-woven fibers, forming a porous structure of high absorption, flexible and resistant to cuts and damages caused by the edges of the plates. They are indicated to replace traditional felt or rubber scrapers, removing excess fluids and contaminants without causing marks and grooves on the surface of the material.

Applied in pickling, cleaning and surface finishing of strips in continuous metal processing lines. These are high-fill-density brush rolls in Multifilament or Monofilament bristles, abrasive or non-abrasive, designed for high performance cleaning of the strip surface with uniform wear and longer lifetime.

Applied in the transportation of strips in horizontal continuous annealing furnaces in galvanizing lines, GO and NGO electrical steels and stainless steel lines, the Furnace Brush Rolls are manufactured with stainless steel shafts and filaments in special alloys, resistant to high temperatures (900 to 1250 ͦ C).

These high-density filament roller brushes offer greater wear resistance compared to traditional centrifuged or ceramic coated rolls, in addition to not allowing scale and oxides to adhere to its surface, generating a defect known as pick-up.

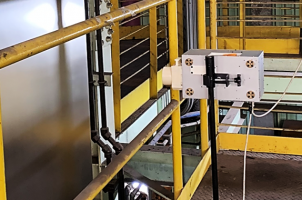

On-line cleanliness diagnostic service without direct contact with the strip, allowing the execution of selected changes in the operating parameters of the line (speed, brush pressure, electrolytic cleaning polarity inversion, among others) and the measurement of the variation in the surface cleanliness level.

Based on the measured results, solutions are suggested to improve the cleaning section by using high performance nonwoven brushes and rollers.

Oil film thickness measurement service using high-precision infrared light. The measurement is performed in a fraction of a second with results in g/m² or mg/m².

Its field of application ranges from post-lamination processes, where oil is initially applied against corrosion, to service centers that need a suitable oil film for cutting and forming processes, or where the absence of oil is essential in the application of coatings or paints on the metal surface.

Service of mechanical and dimensional evaluation of rolls, with the execution of non-destructive tests (liquid penetrant, ultrasonic and magnetic particles), detecting defects and irregularities before they result in serious damage.

Repair of shaft bushings, bearing collars, threads, keys and lubrication channels, restoring the rolls to their original condition.

Dynamic balancing service of shafts and rolls in two planes, performed on state-of-the-art equipment, with a capacity of 3 tons.

The service is performed in accordance with the ISO 1940 Standard, in different classes according to the level of precision required, being classes G 6.3 and G 2.5 the most common for rolls.